Helmholtz Innovation Lab HySprint & KOALA

The combined HySprint and KOALA lab in Berlin serves as a key innovation hub for scalable deposition and advanced characterization of perovskite and tandem solar cells.

Overview

The combined HySprint and KOALA lab in Berlin serves as a key innovation hub for scalable deposition and advanced characterization of perovskite and tandem solar cells. By uniting HySprint’s expertise in inkjet and slot-die printing with KOALA’s advanced infrastructure for large-area device fabrication and industrial reliability testing, the lab enables a rapid transition from research to real-world application.

The lab supports both fundamental research and industry collaboration through high-throughput processes, in-situ diagnostics, and open-format workshops.

Detailed Description

Purpose:

HySprint & KOALA aims to drive the development and industrial scaling of next-generation solar technologies—especially perovskite-silicon tandem solar cells—by integrating lab-scale innovation with production-ready techniques. The lab promotes a smooth pathway from material discovery to commercial viability through a unique combination of processing, diagnostics, and long-term stability testing.

Focus Areas:

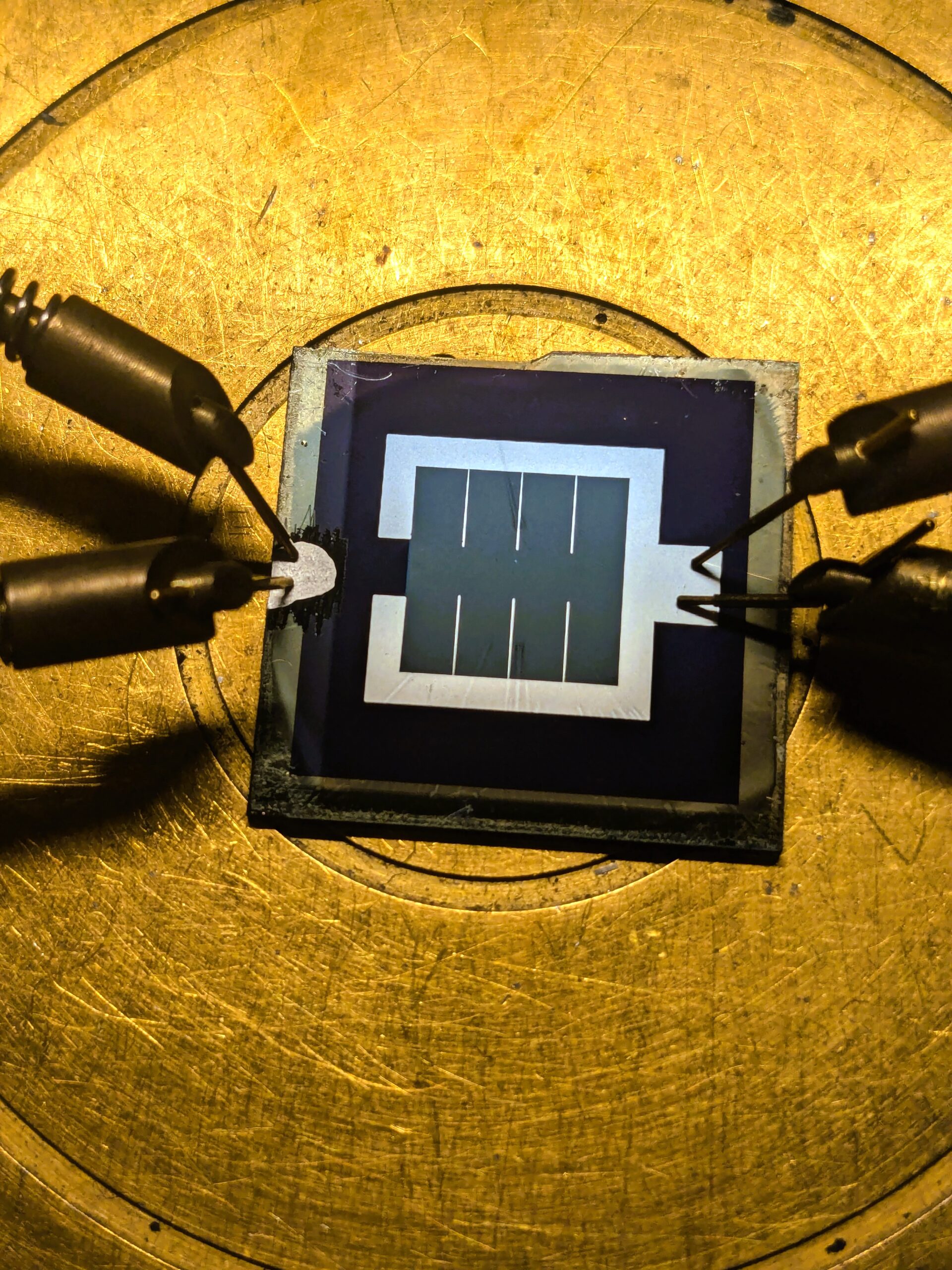

- Scalable processing for perovskite and perovskite/silicon tandem solar cells

- Integration of R&D with industry-grade testing and reliability analysis

- Development of highly reproducible, stable solar modules

- Hosting of demonstration workshops and industry collaborations

Unique Features

- Industrial-grade infrastructure for both inkjet printing (IJP) and slot-die coating (SDC), from lab to pilot scale

- Large-area processing up to 18 × 18 cm for perovskite and tandem solar cells

- Advanced inline and in-situ characterization using optical, electrical, and X-ray methods

- Laser processing in inert environments and packaging under controlled conditions

- Capability to test up to 1024 devices for long-term stability (MPP tracking, outdoor testing)

- Expertise in organizing workshops, open labs, and demos for academic and industrial partners

Processing Capabilities

Active Layers

- Spin coating

- Sheet-to-sheet (S2S) slot-die coating

- Inkjet printing (IJP)

- Blade coating (up to 18 × 18 cm)

- Large-area absorber evaporation (5-source system)

- Vacuum Thermal Deposition (VTD, in planning)

Electrodes

- Thermal evaporation

- High vacuum evaporation in cluster tools

- Atomic Layer Deposition (ALD)

- Inline sputtering tools

Transport Layers

- Spin coating

- Slot-die coating

- Uses same tools as electrode processing

Patterning

- Laser processing (under inert gas)

- Inkjet patterning

Packaging

- Off-line packaging setup

- Laminator / heat press using sealing compounds

Characterization Capabilities

Devices

- Solar simulators (ambient & inert)

- External Quantum Efficiency (EQE) for single and tandem devices

- Dark lock-in thermography (DLiT)

- Light Beam Induced Current (LBIC) mapping

- Electroluminescence (EL) and thermography

- Band Alignment & Contact Extraction (BACE)

- Charge Extraction by Linearly Increasing Voltage (CELIV)

In-line / In-situ Methods

- Photoluminescence (PL)

- UV-Vis transmission and reflectance

- Fourier Transform Photocurrent EQE

- Grazing Incidence Wide-Angle X-ray Scattering (GIWAXS at BESSY II)

Materials & Layers

- Profilometry

- Atomic force microscopy (AFM)

- Scanning electron microscopy (SEM)

- UV-Vis spectroscopy

- Time-resolved PL

- PL and EL mapping

- X-ray diffraction (XRD) and fluorescence (XRF)

- Sheet resistance (four-point probe)

- PL imaging (in setup phase)

Stability

- Stability testing for up to 1024 devices

- MPP tracking setups

- Lifetime test stations

- Outdoor test stand (up to 48 cells)

- Climatic chamber

- Tandem cell testing under inert conditions (24 cells)

Further information

Contact Person

Prof. Dr. Eva Unger

eva.unger(at)helmholtz-berlin.de

Contact Person

Dr. Jona Kurpiers

jona.kurpiers(at)helmholtz-berlin.de