Solar Factory

of the Future

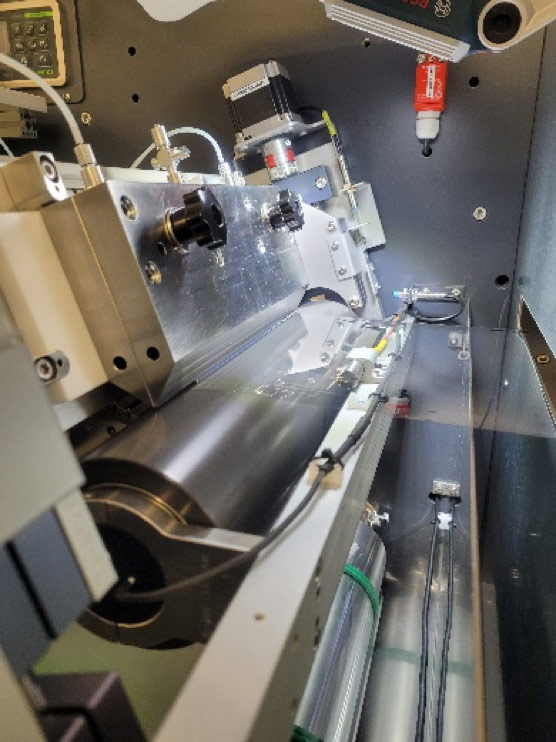

The Roll-to-Roll (R2R) slot die printing machine represents a key component in the Solar Factory of the Future, offering cutting-edge capabilities for the production of organic and perovskite solar modules.

Utilizing advanced slot die coating and laser processes, this industrial machine is capable of producing flexible solar modules at speeds of up to 2 meters per minute. It is perfectly suited for both the prototyping of large-scale solar modules and for high throughput material research.

Overview

The R2R slot die printing machine is an industrial printing machine, which can produce organic and perovskite solar modules by slot die coating and laser processes on a flexible substrate with up to 2 m/min. This machine can be used for advanced prototyping of large-scale modules or high throughput material research.

Detailed Description

Purpose: Solar modules with industrial relevant processes and output can be produced in this infrastructure. The machine consists of three slot die stations, hot air an infrared ovens, web cleaning stations, a inline laser and bus bar lamination. All processes are optimized for a fast and reliable solar module production. Due to the usage of industry relevant processes and materials, perfect prototypes can be made. In addition, the same processes can be used for material qualification and high throughput evaluation, including machine learning.

Videos

Unique Features

- Up to 2 m/min printing with three heatable slot die stations (slot die, baking roll, tubes, syringes) and up to 8 m drying ovens per station

- R2R on-the-fly ns-laser structuring

- High throughput material research, by multi-nozzel slot die and gradient coating of active materials

- Laminated modules with sizes up to 20 x 100 cm² can be produced and are ready for applications

Capabilities

- 3 Slot Die Stations

- Hot air and infrared ovens

- Inline laser

- Cleaning stations

- Various layouts (and due to that voltages) possible, due to laser structuring

- Semi-transparent modules possible with transparent AgNW electrodes

- Inline Spectrometer and contactless sheet resistance measurement as QC

- Rotary screen printer

- Inline Bus Bar lamination

Diagrams or Schematics

Further information

Contact Person

Helmholtz Institute Erlangen-Nuremberg, Forschungszentrum Jülich GmbH

Michael Wagner

mic.wagner(at)fz-juelich.de